785

The 785 Large Mining Truck was Caterpillar’s first entry into the mining industry more than three decades ago and has been a proven performer on sites around the world ever since. And now it’s the first to combine a game-changing level of efficiency with industry-leading physical availability to deliver the next generation of productive hauling. It all starts with the operator, who sits in a state-of-the-art environment designed for efficiency and equipped with features that increase comfort, automate functions, provide real-time information and boost confidence. The 785 also delivers significant improvements in serviceability and reliability, enhanced connectivity and easier technology integration. These improvements — and more — take an already proven truck to the next level of productivity.

PRODUCTIVITY

- The Advanced Power Electronic Control Strategy (APECS) enables faster cycle times thanks to more continuous torque and rimpull.

- Forward momentum and torque are maintained through each shift, with optimum gear selection resulting in faster acceleration.

- The 785 delivers a 6% higher TKPH /TMPH (tonne-kilometer-per-hour / ton-mile-per-hour) thanks to larger tire options that allow allow mines to take advantage of higher speeds, particularly in flat, long-haul, high-speed applications.

- Productivity-enhancing features such as Hill Start Assist with Anti-Rollback, Enhanced Traction Control, Dynamic Stability Control (DSC), Anti-lock Brake System (ABS), Machine Speed Limiting and Cruise Control improve machine responsiveness and controllability while improving cycle times and reducing operator fatigue.

SAFETY

- Wide, slip-resistant surfaces and hand rails, plus an optional powered access ladder, improve access and egress.

- Superior control is delivered by a patented braking system that provides immediate, fade-resistant braking and retarding.

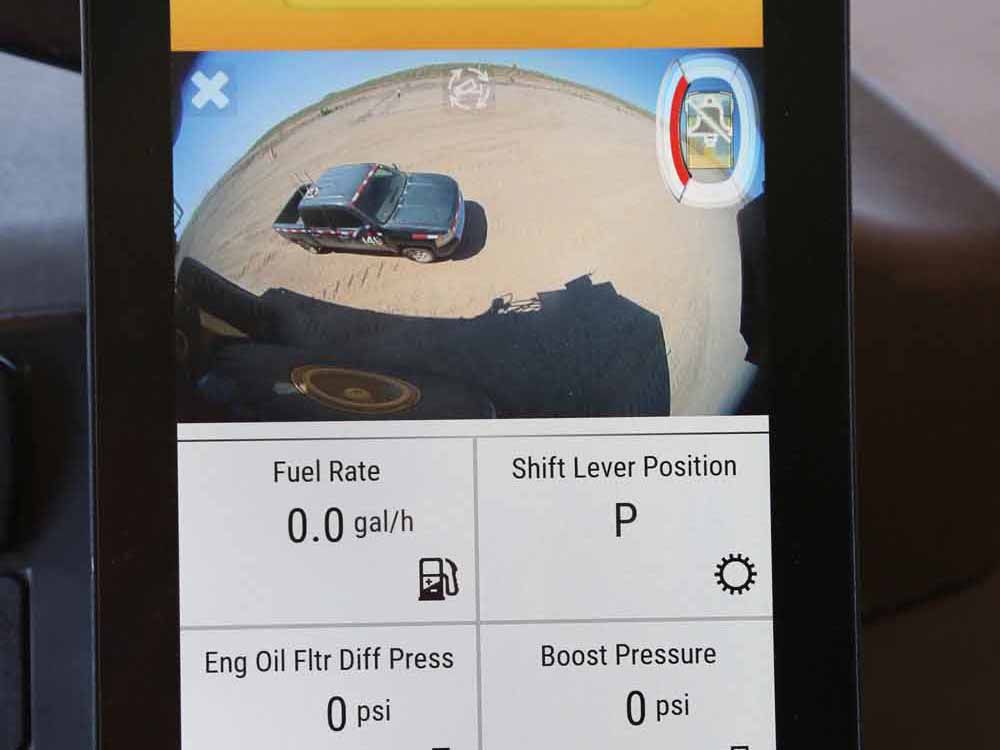

- Visibility is enhanced by an optional 360-degree Surround View camera, which offers a bird’s-eye view.

- The Cat MineStar™ Object Detection system combines radar and camera systems to warn operators about light vehicles or stationary hazards within the immediate vicinity of their machines.

- The optional Driver Safety System alerts the operator if fatigue or distraction are detected.

OPERATOR COMFORT

- The cab provides 34% more operator space than D-Series models. It’s 17% wider and offers 11% more legroom and 19% more shoulder room. Controls, levers and switches are positioned for ease of use.

- With 40% less Sound Pressure Level (SPL), automated temperature control and cab filtration, operators enjoy a safer and more comfortable environment.

- A walkthrough cab with fully adjustable center console, easy-to-adjust seat and increased leg room makes the cab ideal for operators of all sizes.

- The next generation seat is four-point-restraint ready and incorporates features like thigh tilt and extensions, air adjustable side and lumbar bolsters, and heated and cooled cushions.

- Operators enjoy a more comfortable ride thanks to smoother transitional shifting and reduced shift jerk levels provided by APECS controls.

OPERATOR EFFICIENCY & PRODUCTIVITY

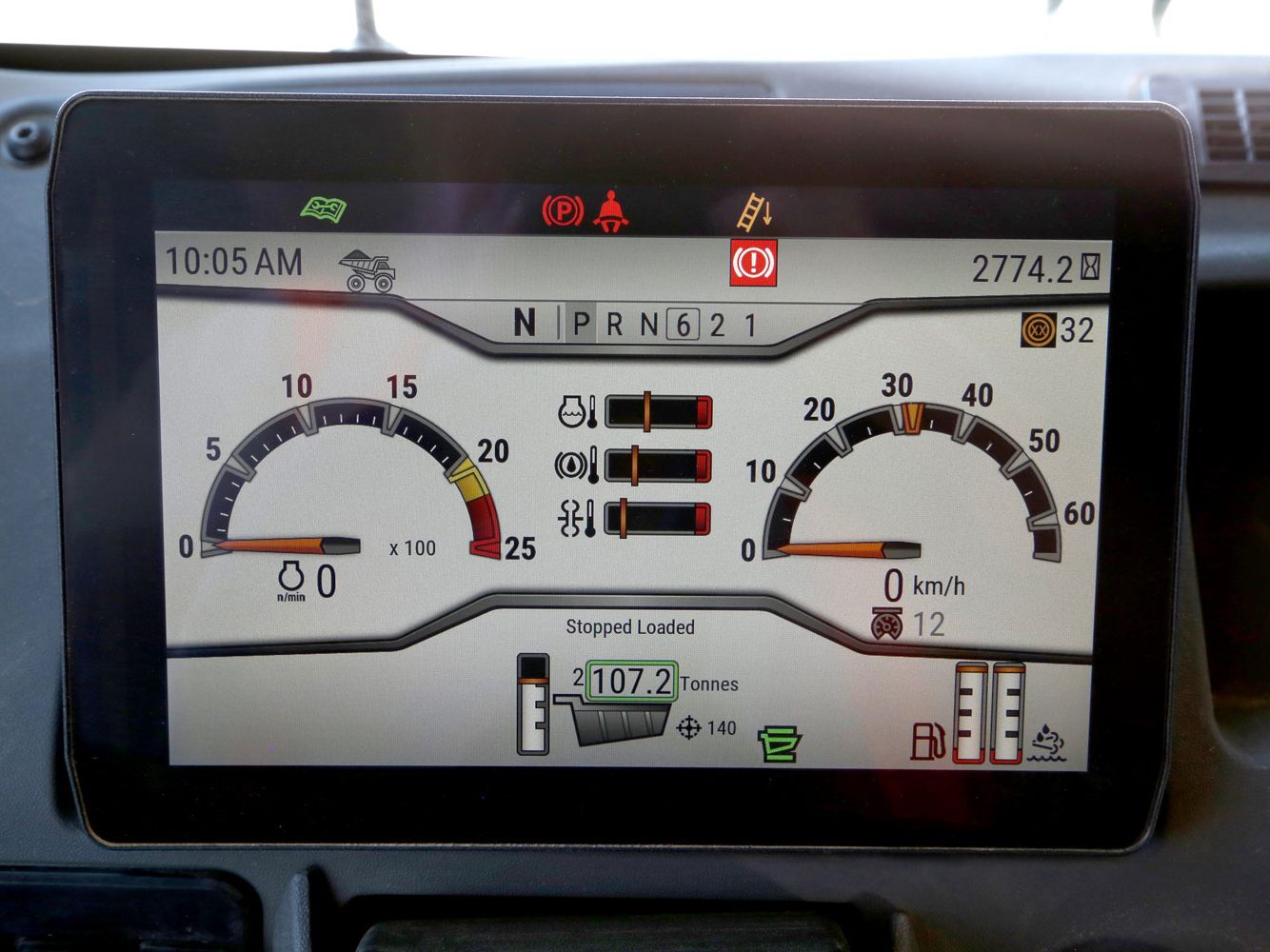

- Higher resolution displays improve access to information. Machine data, controls and guidance information are consolidated onto two ideally located 10-inch screens.

- The optional Auto Hoist feature automatically raises the body and controls engine speed, simplifying operation and minimizing cycle times.

- Speed coaching gives operators real-time feedback on how to operate the truck to maximize its productivity.

- The payload monitoring system comes with more accurate measurements, providing immediate feedback to the operator.

SERVICEABILITY

- The new modular HVAC (heating, ventilation and air conditioning) system improves reliability and consolidates components so the entire system can be removed and replaced quickly.

- A modular radiator reduces engine removal and installation time and enables rebuilds to be completed off the truck.

- New remote flash and remote troubleshooting capabilities provide immediate access to the latest software updates and make it possible to troubleshoot the machine remotely.

- Time spent on regular maintenance procedures is reduced thanks to features such as extended-interval filters with ground-level access; grouped service points and optional centralized service center; cleaner hydraulic and electrical routings; SOS and pressure ports for faster, safer oil sampling and troubleshooting; and fluid-level sight glasses.

- A 100% airless electric start option eliminates air system maintenance from the machine and improves uptime.

DURABILITY AND LONG LIFE

- Longer-life components, extended service intervals and easier maintenance deliver consistently high mechanical availability.

- A reduction in torque spikes and fewer variations in engine speed, made possible by APECS controls, deliver longer engine and powertrain component life.

- The 785 frame uses a box-section design, incorporating two forgings and 21 castings in high-stress areas with deep penetrating and continuous wrap-around welds to resist damage from twisting loads without adding extra weight. The mild steel frame provides flexibility, durability and resistance to impact loads.

- Component life is enhanced thanks to the standard rear-axle continuous filtration feature. Cleaner oil helps promote lubrication that leads to longer life

- The frame, powertrain, engine and components are built to be rebuilt — delivering multiple lives of like-new performance at a fraction-of-new price.

CAT BODIES

- Caterpillar designed and manufactured bodies are integrated with the chassis as a unit to optimize performance and incorporate optional Tier 4 components, including body exhaust heat.

- The lightweight Mine Specific Design (MSD) body is designed with built-in carryback reduction features (front wall curved transition and corner pop-out plates) and is available with optional application-specific body liners.

- Intended for tough applications, the heavy-duty Dual Slope body provides excellent load retention, maintains a low center of gravity with optimum load distribution and reduces shock loading.

SUSTAINABILITY

- The 785 is designed to use less fuel, which reduces engine emissions, and there is zero fuel burn during retarding. The Tier 4 Final engine reduces NOx and particulate matter.

- The Cat 3512E engine’s 12-cylinder four-stroke design uses long, effective power strokes for more complete fuel combustion and optimum fuel efficiency.

- The 785 engine is compatible with diesel fuel blended with lower-carbon intensity fuels such as biofuels and renewable fuels.

- Features like oil renewal systems, continuous rear axle filtration, extended life filters and longer maintenance intervals decrease the amount of waste contributed to the environment.

- By rebuilding machines and components, the Cat Rebuild and Cat Reman programs preserve raw materials, conserve energy and reduce emissions.

VERSATILITY

- The 785 is available in a cold-weather configuration that makes it ideal for mines operating in frigid environments. It features automatic engine thermal management, a variable fan speed for low temperature operation, and an electric- or air-start option.

- The 3512E engine gives you the ability to select the power rating to match your current fleet performance or to achieve faster cycle times.

- The 23% net torque rise provides unequaled lugging force during acceleration, on steep grades and in rough underfoot conditions.

- Tire options allow you to select the tire that best matches your application, with a larger tire for flat, long, high-speed applications. The frame is designed to maintain the same turning diameter while accommodating larger tires.

- The 785 is available in two options to meet emissions standards. The optional Tier 4 Final engine meets the strictest standards while the LRC engine is available in those countries that are less regulated.

TECHNOLOGY SOLUTIONS

- MineStar Fleet is a fleet monitoring system that can be used to measure, manage and maximize the overall hauling operation.

- Additional MineStar Detect offerings include Awareness, which can provide warnings, and the in-cab Driver Safety System, which intervenes when it detects fatigue or distraction.

- Machine health and condition monitoring solutions enable a proactive approach to maintenance.

BETTER ACCESS TO DATA

- Next generation connectivity delivers faster data transfers, better access to data, consistent data communication, more actionable data, improved data analytics and new diagnostic capabilities.

- The backbone of the next generation machine is 100 Mbps two-wire ethernet communication across the machine controllers, sensors that are optimized for data analytics, and robust controls.

- Advanced connectivity on the 785 truck is enabled by standard cellular 4G/LTE, optional dual mode 4G/LTE and Satellite Product Link™, or locally installed Wi-Fi.

- Every machine from the factory comes with Product Link Elite as a standard offering. This solution enables the truck to collect and transmit information into locally-hosted or cloud-hosted applications.